The first step is to start the material, and there are several options.

Beginners can go to the online shop to buy ready-made, that is, machine-cut and punched good rough ring material. They are already well-drilled and easy to make later. This is a lot of energy saving for girls. I am used to buying small-leaf rosewood scraps directly, you must read the comments to choose. Rosewood is a precious rosewood, and the cheap ones must be fake.

I’m using a triple saw to cut the material. Draw the inner circle in pencil and fix the four points. It is worth noting that the size of the ring must be two millimeters larger than the size of your finger. It’s for sawing and grinding. Be sure to do subtraction in the process of production, otherwise the subtraction can not be added back at the beginning.

Saw off the core and corners

The saw blade of a wire saw is a cylindrical saw blade rolled up by a particularly narrow thin saw blade, so it can be sawed in any direction, so it is called a “universal saw”. It is commonly used as a patterned showpiece. The saw blade can be removed and replaced, so it is necessary to remove the saw blade through the drilled hole and fix the wood with a vice. This process should be even! Be sure to even the force! Don’t push too hard, or you’ll break several blades to make a ring.

When sawing carefully, follow the line of the saw, as round as possible, and do not cut into a thick and thin hole. Don’t be like me. I’m too lazy to draw lines.

Start grinding the inside diameter

At this time, do not rush to saw off the four corners, because it is more convenient to hold and polish. When the hole is relatively small, you can first use a pencil rolled 80 grit sandpaper in circles or back and forth grinding. When polishing the inner diameter, especially when finishing, be sure to rotate the grinding, so that it is easy to round. Grinding the inside diameter is a blank, so use a thicker sandpaper. When sanding, you will smell a very good smell of sandalwood, but the sandalwood of small-leaf rosewood is not like the sandalwood of falling rosewood, and the two kinds of wood are not the same. The smell is different. It’s more like chocolate. You’ll know by smelling it yourself.

Fix your work

You can try it on while you’re polishing the inside. The grinding process must be patient, do not hurry! After you have polished the inner circle, saw off the four corners or simply ground off the four corners. Now you need a flat, hard surface, put the sandpaper on it and hand sand it. Because of the fear of making mistakes in the middle, the thickness is relatively thick, and the thickness should be repaired at this time, that is, the thickness is controlled according to the different needs of men and women. Of course, women can wear a wider ring, and men can wear a tighter ring. It all depends on your own preferences.

Finish the work

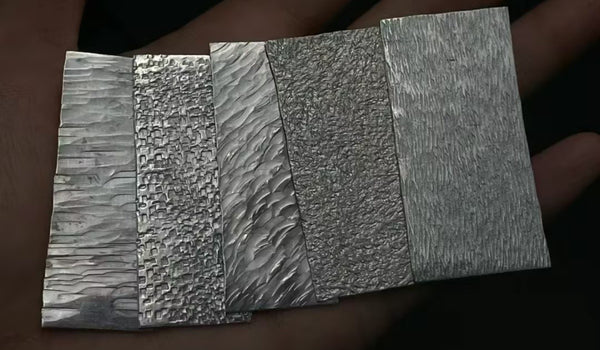

Complete this step and you are halfway there! The process is longer and more tedious. You need to keep checking the thickness, keeping the thickness even. There are two kinds of cross-sections of the ring, one is a semicircle and the other is a rectangle. I’m used to grinding it like this, which is a rectangular section. If you like it, you can start polishing it now. But polishing is step seven. Wait until I finish step six!

Round

Due to the difference in cross-section, it can be distinguished into rectangular cross-sections and circular cross-sections. When I usually make a rectangular cross-section ring into a round cross-section ring, I need to round the corners. That is, to polish the edge right Angle into a rounded corner, this must be extra careful. This process is still slowly grinding, grinding while watching. Take the sandpaper into your hand and put the ring on the finger of the other hand. Be sure to apply even force, not hard, and be careful to crush. In the most comfortable, your own best way to polish, there is no fixed way, as long as you can do something good even a good way.

Polish

Once the blank is fixed, it’s polished. But polishing is definitely not easy. 80 mesh is the number of sandpaper mesh used to repair the blank, and 240 mesh, 400 mesh, and 600 mesh are the number of roughed sandpaper mesh. The sandpaper effect of these numbers is relatively fast. But remember, be sure to use high mesh sandpaper to carefully grind out the marks of low mesh sandpaper. 800 mesh and 1000 mesh are high-polishing sandpaper, hardback and forth fast grinding, and sandpaper cut to the right size when used.

Apply beeswax

This step is optional, there is no need to use beeswax. Lobular rosewood oil is very high, as long as the humidity and temperature change are not too large, and generally not easy to crack. Of course, beeswax is a hard wax, hardness and toughness are relatively high. The molecular structure of beeswax will fill the brown eyes and molecular gaps of the wood, thereby tightening the wood molecules, which can ensure that the wood is not easy to crack to a certain extent. Then melt the beeswax in a metal, ceramic, or glass container with an alcohol lamp or gas stove, and place the ring inside for a few seconds. If it bubbles, it means that in the penetration of the ring, do not take too long to coke or boil the wood.

After taking it out, the hot air of the hair dryer blows off the excess beeswax, and if you can’t blow it off, scrape it with your nails, and then polish your hands gently with 800 mesh.

When your strength and endurance are almost exhausted, your ring is finally made, whether it is for a man, a woman, or a gift for yourself. Don’t wear dirty, sweaty, greasy hands! It’s normal to lose color in the early stages.

View more related articles

The best tutorials for hand carving

Carving History and Culture: Art That Spans the Ages

Katway München Jewelry Show Guide

The Importance of Hand Engraving and the Reason We Employ It