Whether you are a novice in jewelry making or a professional jewelry studio, a rolling mill is an essential tool. It can bring endless creative possibilities to your jewelry making. From rolling basic metal sheets to well-proportioned metal wires, a jewelry rolling mill prepares excellent materials for your exquisite works.

What is a Rolling Mill?

A rolling mill is a metal forming tool. Its main function is to process and shape the metal blanks coming out of the furnace and process the metal into different specifications. It is widely used in jewelry making.

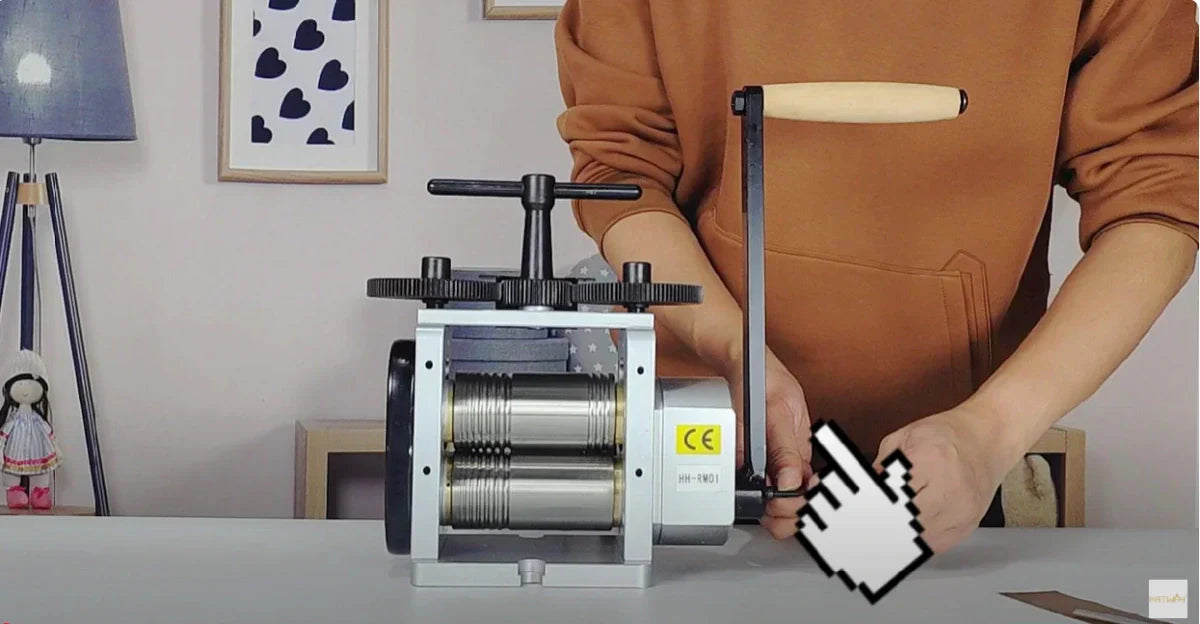

The structure of the rolling mill machine is not complicated. It has two hard steel rollers installed in pairs (upper roller + lower roller) to apply pressure to the metal for rolling.

In addition, it has a gear transmission system connecting the handle and the rollers, so that the two rollers rotate at the same time. There is an adjusting screw at the top to adjust the gap between the upper and lower rollers to control the thickness of the rolling.

The manual rolling mill has a rocker arm to drive the gear transmission system. The rocker arm is usually longer and the labor-saving effect is very obvious. The motor-driven rolling mill does not have a rocker arm.

These parts are assembled on the frame, so the main structural frame of the rolling mill is often made of cast iron or steel, which is very strong and can withstand high pressure.

The bottom of the rolling mill usually has a base or fixing hole for fixing on the workbench.

How to Use Rolling Mill?

Using roll mills is very simple, so don’t worry if you are new to it. We have compiled all the tips on how to use a roll mill and the best ways to use it for your reference.

Install And Secure Your Metal Rolling Mill

Since the mill is very heavy, you must have a sturdy workbench to ensure that the mill can work properly. It is very important to fix the machine firmly on the special mill stand. There have been some accidents in the past where the mill was not fixed and the machine rolled off the workbench during use and injured people.

New mills do not need lubrication. They are already lubricated before leaving the factory. So you can use it directly after fixing it. If you buy a second-hand mill, it is recommended that you check whether the gear transmission system is dry before using it.

How to Roll Sheet?

Rolling sheet metal is one of the most common uses of a rolling mill. It can be used to make the sheet uniform in thickness, adjust the thickness of the metal, or prepare it for subsequent processing. Prepare a clean and annealed piece of metal.

Next, adjust the rollers on your mill to slightly more than the metal’s current thickness. Slide the sheet in, then tighten the rollers until they just grip the metal. Remove the sheet, tighten slightly more (about a quarter turn), and you’re ready to roll.

Crank the handle smoothly to pass the sheet through, keeping it flat and steady. After the first pass, reduce the roller gap gradually with each turn, rolling again until you reach your desired thickness. For large reductions, anneal the metal between passes to prevent work hardening.

Check thickness regularly with a caliper to ensure consistency, and avoid rolling too much at once. Once finished, clean both the metal and the rollers. Proper rolling produces an even, smooth sheet that’s ready for forming, texturing, or soldering.

How to Roll Wire?

Rolling wire with a rolling mill is a useful way to reduce its diameter, shape it more uniformly, or prepare it for drawing through a drawplate. Start by selecting the grooved section of your combination rolling mill—the part designed specifically for wire rolling. Make sure your wire is clean, straight, and annealed to prevent cracking.

Place the wire into the appropriate groove that closely matches its current size. Adjust the rollers so they grip the wire firmly without flattening it. Turn the handle steadily to roll the wire through. After the first pass, reduce the gap slightly and roll again. Repeat this process in small increments until you achieve the desired thickness or shape.

For dramatic size reduction, anneal the wire between passes to keep it ductile. Use a caliper to measure the wire as you go, ensuring uniformity. Once done, your wire will be more consistent in diameter and ready for further shaping, twisting, or fabrication work.

Benefits of Using a Rolling Mill in Jewelry Making

A rolling mill is one of the most valuable tools in any jeweler’s studio—not just for shaping metal, but for expanding creative possibilities. Its versatility allows you to work with both sheet and wire, and even to imprint textures using pattern plates or organic materials. Whether you’re refining your own metal or creating unique surfaces, a rolling mill offers unmatched control.

Rolling your own metal saves time and money by eliminating the need to purchase multiple gauges, while also ensuring precise results tailored to your project. With a properly maintained machine, you can achieve professional-quality finishes for decades.

Here are just a few reasons why a rolling mill can quickly become one of your most-used tools:

- Versatility: Roll sheet and wire, emboss textures, and create unique metal forms.

- Efficiency: Reduce metal stock yourself to the desired gauge.

- Precision: Achieve accurate thickness and uniform results.

- Creativity: Add patterns using texture plates or natural materials.

- Durability: A well-maintained rolling mill can last a lifetime.

- Professional Results: Clean, consistent finishes elevate the quality of your work.

Best Practices When Using a Rolling Mill

Using a rolling mill correctly not only ensures better results but also helps protect both your tools and materials. Whether you’re working with sheet or wire, following a few essential guidelines will maximize the life of your mill and the quality of your metalwork.

First, always make sure your metal is clean, dry, and annealed before rolling. Dirt or oxidization can scratch the rollers, while hardened metal can crack or distort. Annealing softens the metal, making it easier to roll without damaging the mill or producing uneven results.

When adjusting the roller gap, take it slow. Reduce thickness gradually, turning the adjustment screw in small increments—usually no more than a quarter turn at a time. Forcing too much metal through too narrow a gap can permanently damage the rollers or cause slippage.

Use the right section of the rollers for the job. Combination mills usually have flat areas for sheet and grooved sections for wire. Avoid rolling textured or contaminated materials directly on the flat rollers unless using a proper texture plate or backing sheet.

After each session, clean the rollers with a soft cloth, and lightly oil them if you live in a humid environment. This prevents rust and extends the life of your equipment. Never store metal between the rollers, as this can create pressure points and warping over time.

Quick Tips:

- Always anneal metal before rolling

- Adjust rollers in small increments

- Use proper grooves for wire

- Clean and oil rollers regularly

- Avoid rolling dirty or hard metal directly